ABOUT US

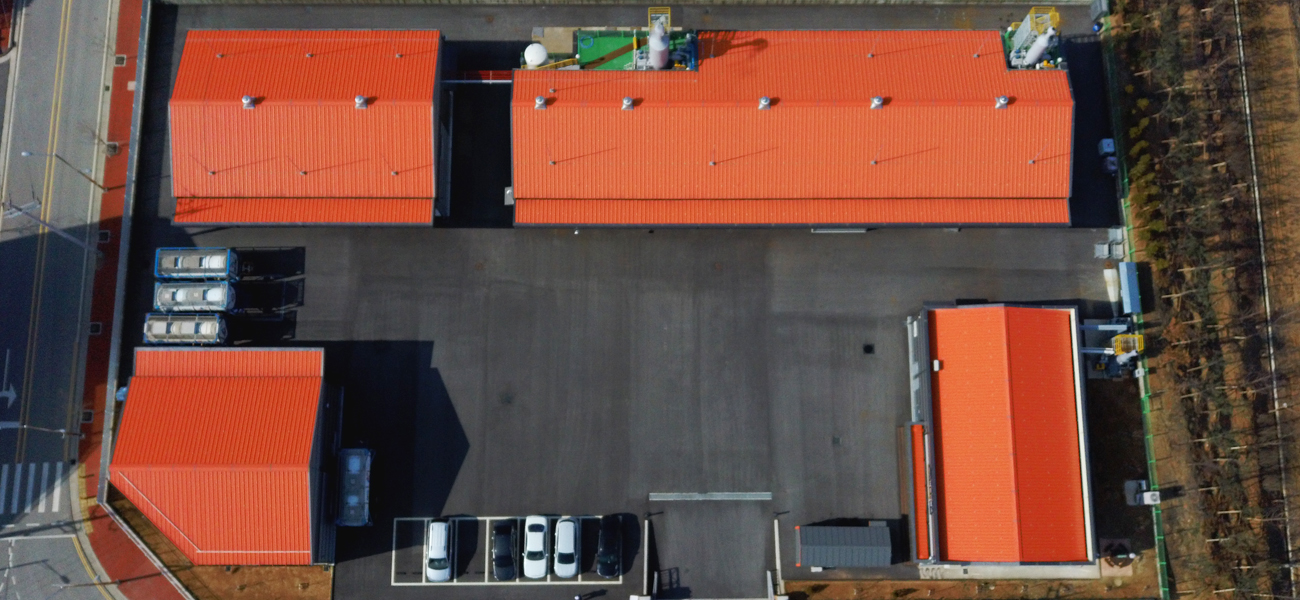

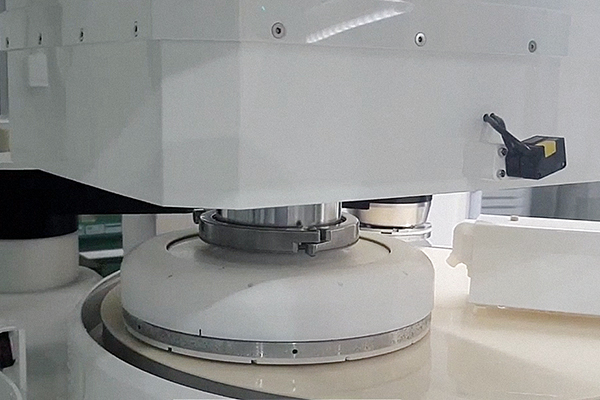

MS Materials is a material company that manufactures and sells gas and chemical materials for semiconductor and display manufacturing processes.

Started as a gas analysis business in special gas and general gas in 2008, MS Materials is a specialized materials company that manufactures and sells special gases for semiconductor, precursor, silicon wafer manufacturing and slurries for CMP, MEMS processes. With ongoing technology development to keep pace with the growth of domestic and overseas semiconductor and display industries, MS Materials is playing a pivotal role in the domestic and overseas material markets.

MS Materials aims to grow with the customers, constantly seeking new challenges, embracing innovation for continuous growth.

Thank you.

Quality Mgmt System

Quality Mgmt System

OHSAS 180001 (Safety & Health Management System)

OHSAS 180001 (Safety & Health Management System)

Environment Mgmt System

Environment Mgmt System

Certificate of company affiliated research

Certificate of company affiliated research

ESH Compliance

ESH Compliance

Safety Inspections

Safety Inspections

Emergency Action Plan

Emergency Action Plan

Safety & Health Training

Safety & Health Training

Customer Satisfaction

Customer Satisfaction

Maximizing Profit

Maximizing Profit

Improving & Controlling

Improving & Controlling